Lev Khazanovich

Lev Khazanovich“Implements of husbandry (IoH)” refer to vehicles that are exclusively used for agricultural purposes, such as planting; seeding; cultivating; harvesting; applying nutrients, fertilizers, or chemicals; or transporting agricultural products and supplies to and from farms. These vehicles include tractors, attached equipment (e.g., tankers, manure spreaders, plows, cultivators, and combines), and trucks. While primarily used on farms, IoH frequently travel on roads and bridges.

Over the past few decades, the size and weight of IoH have significantly increased because of the consolidation and growth of farming operations. However, many state practices for roads carrying IoH have not kept pace with these changes. While there has been extensive research on the effects of truck traffic on pavement performance, limited research has focused on quantifying the influence of IoH on pavement performance. Heavily overloaded IoH have been known to cause pavement distress or failure, but there are no nationally accepted procedures for estimating these effects.

The National Cooperative Highway Research Program (NCHRP) initiated Project 01-58 to propose procedures for quantifying the effects of IoH on pavement performance and develop a user-friendly tool to facilitate their implementation. A research team from the University of Pittsburgh and Minnesota Department of Transportation conducted a comprehensive review of current state limits (e.g., weight restrictions) on IoH, as well as other potential challenges for pavements related to IoH. The team also analyzed typical IoH characteristics and reviewed the available literature on analytical and field investigations related to evaluating the effects of IoH on pavement performance.

Through this process, potentially important factors for estimating IoH effects on pavement performance were identified. To enhance mechanistic–empirical models for determining IoH damage and its contribution to pavement deterioration for flexible (asphalt) and rigid (concrete) pavements, models for computing structural responses because of IoH were developed and incorporated into an easy to use desktop tool. The procedures and software tool for estimating IoH impacts are presented in NCHRP Research Report 1019: Quantifying the Effects of Implements of Husbandry on Pavements and accompanying resources.

Current Practices

Despite the significant increase in IoH loads over the years, state department of transportation (DOT) practices governing IoH loads have remained largely unchanged. Some states, such as Alabama, Idaho, Nevada, and North Carolina, exempt IoH from state regulations on allowable loads. Other states have restrictions on maximum gross weight and axle weight based on pounds per inch of tire width. Minnesota, for example, applies a value of 500 pounds per inch of tire width, while in North Dakota the value is 550 pounds per inch of tire width. In addition, a survey of state DOTs was conducted to obtain information on the following:

- Procedures used to evaluate damage from overweight loads on pavements,

- Performance data or research findings related to the effect of overweight loads on pavements,

- Types of husbandry equipment typically used, and

- Weight restrictions imposed on husbandry equipment.

Jason Lim

Jason LimThose state DOTs that responded to the survey generally do not have special procedures to evaluate damage from overweight loads on pavements beyond their heavy load permitting process. Respondents also reported having limited performance data documenting the effect of overweight loads on pavements. Several states provided detailed information on the types of IoH typically used in their state, including tractors pulling tankers or manure spreaders, nutrient spreaders, plows, chisel plows, discs, ripper discs, soil finishers, corn planters, forage boxes, bale processors, cultivators, and combines. Weight restrictions on IoH varied greatly among states. Some have none, some treat IoH the same as any other vehicle, and others have exemptions and restrictions on IoH—depending on the circumstance.

The study—conducted under NCHRP Project 01-58 and reported in NCHRP Research Report 1019—identified axle weight, tire footprint, and axle spacing of IoH vehicles as the key characteristics that distinguish their effects on pavements from typical trucks.

Weight

The axle weights and gross vehicle weights of IoH may significantly exceed the typical weights of commercial vehicles with the same number of axles. This increased weight can exert higher loads on the pavement surface, leading to potential damage. Table 1 shows the maximum and gross axle weights for the vehicles used in the tests conducted at Minnesota DOT’s pavement test track, MnROAD, under a pooled fund study—TPF-5(148)—sponsored by the Iowa, Illinois, Minnesota, and Wisconsin DOTs, with Minnesota DOT acting as the lead agency. Every IoH used in the tests had at least one axle heavier than the legal axle-weight limit. The lightest IoH—homemade trucks with 4,400-gallon tanks—had axle weights similar or higher than those for the 102-kips truck that was used to study the effect of overloading at the MnROAD low-volume loop.

TABLE 1 Axle and Gross Vehicle Weights for Vehicles Tested Under TPF-5(148) Pooled Fund Study

| Vehicle ID | Vehicle Type | Size | Number of Axles | Max. Single Axle Weight (kips) | Max. Tandem Axle Weight (kips) | Max. Total Vehicle Weight (kips) |

|---|---|---|---|---|---|---|

| 1 and 2 | Truck | 4,400 gal. | 2 (1 Single + 1 Tandem) | 19 | 48 | 65 |

| 3 | Grain Cart | 1,000 bushels (9,309 gal.) | 3 (3 Single) | 57 | na | 87 |

| 4 | Terragator | 2,300 gal. | 2 (2 Single) | 30 | na | 47 |

| 5 | Terragator | 4,200 gal. | 2 (2 Single) | 42 | na | 75 |

| 6 | Tanker | 6,000 gal. | 3 (2 Single + 1 Tandem) | 27 | 61 | 90 |

| 7 | Tanker | 7,300 gal. | 5 (5 Single) | 27 | na | 115 |

| 8 | Tanker | 9,500 gal. | 6 (6 Single) | 37 | na | 153 |

| 9 | Semi-Truck | na | 3 (1 Single + 2 Tandem) | 13 | 38 | 80 |

| 10 | Semi-Truck | na | 3 (1 Single + 2 Tandem) | 13 | 50 | 102 |

Note: na = not applicable; kip = 1,000 pounds-force.

Tire Footprint

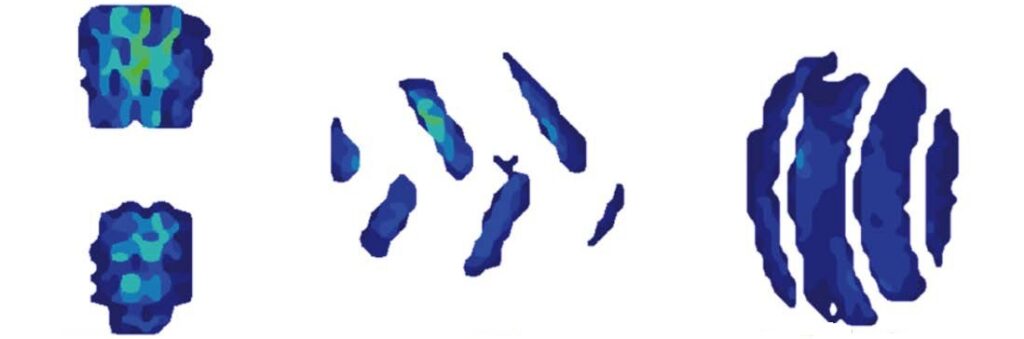

Some IoH vehicles are designed to travel on soil and, thus, are equipped with large-diameter tires that have low pressure and produce a large footprint. This unique tire footprint can result in loads on the pavement surface that lead to accelerated wear and damage. Table 2 presents comparisons of several tire characteristics of two types of tires commonly used for IoH semi-trucks. The footprint geometry of IoH tires may also vary. The tire footprints collected under the TPF-5(148) study were classified into three types, as shown in Figure 1. Type 1 is a single or double footprint of roughly square shape; Type 2 has multiple scattered footprints; and Type 3 exhibits multiple elongated and clustered footprints.

Jason Lim

Jason LimTABLE 2 Comparison of Commercial and IoH Truck Tire Characteristics

| Tire Parameter | Commercial Truck | IoH |

|---|---|---|

| Diameter | 33.3 inches | 61.7 inches |

| Width | 10.5 inches | 29.1 inches |

| Maximum Inflation Pressure | 130 psi | 45 psi |

| Maximum Load | 6,940 pounds | 17,400 pounds |

Note: psi = pounds per square inch.

Axle Spacing

Because of larger wheel sizes, the distances between individual axles in IoH may be greater than the typical spacing within tandem and tridem (i.e., group of three) axles for commercial trucks. As a result, IoH may tend to travel closer to the pavement edge, increasing the likelihood of causing greater damage there. Moreover, the different axle configurations of IoH can result in varying pavement responses that contribute to pavement damage, compared with typical trucks.

Lev Khazanovich

Lev KhazanovichThe current pavement design software—AASHTOWare Pavement ME Design—accounts for most of these factors, it has limitations that are important for modeling the effects of IoH on pavement performance. AASHTOWare Pavement ME Design, which combines traffic data with pavement responses to evaluate pavement performance, is generally intended for a large number of truck passings that individually cause very little damage. However, though their volume is generally low, IoH vehicles can cause greater damage to the pavement. Thus, the development of new tools and performance metrics was necessary.

Analysis of IoH on Flexible and Rigid Pavements

The AASHTOWare Pavement ME Design model uses layered elastic theory, which makes certain assumptions about the pavement properties and truck load that do not necessarily apply to IoH vehicles. To account for the effect of speed and size of the tire footprint for IoH vehicles, the NCHRP study adopted a layered viscoelastic theory model. In this approach, the asphalt layer is modeled as a viscoelastic layer, while other layers are modeled as elastic. Solutions to layered viscoelastic theory problems are computationally extensive (i.e., require more time and expense), which make it difficult to use this method in pavement engineering where solutions at multiple points are typically required. Therefore, a computationally efficient method that requires less time and money was developed. This approach was incorporated into a new program, PittLAYER-VE, whose predictions were validated by measured responses from an instrumented section of the MnROAD test facilities. Additionally, finite element modeling—a numerical analysis method—was used to adjust the strain values near pavement edges or partially unpaved shoulders for IoH vehicle loads.

Critical stresses and deflections in concrete pavement occur under a combined effect of axle loading and concrete slab curling and warping. Many factors affect the magnitude of bending stresses in rigid pavements, which the AASHTOWare Pavement ME Design software tool potentially could be used to model the response under IoH loads by modifying the default inputs. However, this approach was found to be inadequate, particularly in view of nighttime temperature gradients. Therefore, the research team trained neural networks (i.e., machine learning tools that can model complex input–output relationships) to develop rapid solutions. To reduce the number of required simulations, an approach was adapted from NCHRP Project 01-37A, “Development of the 2002 Guide for the Design of New and Rehabilitated Pavement Structures: Phase II” that significantly decreases the independent variables for neural network inputs. This permitted an increase in the accuracy of prediction with the same number of finite-element simulations.

Damage Modeling

The AASHTOWare ME Design procedure uses the incremental damage approach, in which a single repetition of a load causes minuscule damage; these add up over time with a large number of load repetitions. However, because IoH vehicles generally have far fewer repetitions (i.e., travel on the road less frequently) than conventional trucks, this approach cannot directly be used. Instead, a new parameter—called the equivalent number of trucks—was developed to approximate the number of standard truck repetitions that would cause the same amount of damage as a single IoH vehicle repetition. This equivalent number depends only on the relative damage caused by the two types of vehicles and not on the number of repetitions, which makes it suitable for analysis of IoH vehicles. This approach was adopted for asphalt and rigid pavements. Additionally, for rigid pavements, the number of IoH load applications required to produce substantial fatigue damage was also evaluated.

In addition to causing distress in the asphalt and concrete layers, the heavy loads of IoH vehicles also generate a potential for shear failure in the subgrade (i.e., when the soil underneath the pavement slides because it loses its ability to support the weight and movement of vehicles). To account for such cases, a new metric was developed: the Relative Shear Strength Ratio. This metric, which is the ratio of the Shear Strength Ratio of the subgrade under the IoH load to that under a standard truck load, allows for quantification of the effect of a single pass of an IoH vehicle. Laboratory investigations were also conducted to establish the effect of freeze–thaw cycles on the Shear Strength Ratio for various subgrade materials. However, the test protocol adopted did not reveal a substantial effect. Suitable rudimentary software tools were developed to calculate these performance metrics automatically.

Findings and Future Work

The procedures developed in this study were utilized to analyze the damage caused by various types of IoH vehicles on pavements with different characteristics and climate conditions. The findings revealed that a single pass of an IoH vehicle could result in greater damage than multiple passes of standard commercial vehicles that meet legal axle-weight requirements. This is particularly significant for thin flexible and thin rigid pavements, as heavily loaded IoH vehicles can significantly reduce service life or even cause immediate failure. The damage caused by a single IoH pass tends to decrease with thicker pavements. However, the relative damage from IoH compared with standard commercial trucks may increase with pavement thickness. Furthermore, thicker pavements are typically constructed for high-volume roads, and if the volume of IoH traffic is substantially lower than that of heavy trucks, the overall impact of IoH on the performance of high-volume roads may be modest.

The predictions of the models developed in this study were compared with observations from full-scale tests conducted at MnROAD. The analytical predictions were consistent with field observations. Thin asphalt sections exhibited extensive cracking, severe rutting, and failure after several passes of heavily loaded IoH vehicles, while thinner concrete pavements experienced corner breaks. In contrast, thicker flexible and rigid pavements did not exhibit any distresses after the same number of IoH load applications, suggesting that overloading of thin flexible and rigid pavements should be avoided. The use of paved shoulders for flexible pavements and tied portland cement concrete shoulders (i.e., concrete shoulders with steel reinforcing bars across the joint between the shoulder and main pavement) for rigid pavements was found to reduce the IoH-induced critical structural responses, as predicted by the procedure developed in this study and the measured structural responses at MnROAD.

This research highlighted the need for calibrating damage models for IoH vehicles, particularly those for longitudinal cracking initiation and propagation. It also indicated a need for evaluating the effect of thawing on base shear strength and developing an improved protocol for shear-strength testing to quantify the reduction in shear strength. Incorporating the developed procedures into the AASHTOWare Pavement ME Design software could provide a means for better estimation of the effects of IoH on pavement performance.